Cooper is not just Cooper!

There is not just one type of cooper in Germany. There are wine coopers and wood coopers. Why? What exactly are they doing?

Let’s take a closer look at the differences!

Wine cooper

A wine cooper is a specialist in production, storage, and care of wine and other beverages such as cider or spirits. The term originates from the traditional designation for craftsmen involved in winemaking and storage. Today, the profession is officially known as “wine technologist” in Germany.

History of the profession

The origins of the wine cooper date back to the Middle Ages when winemaking was often practiced by monks in monasteries. Wine coopers were responsible for the fermentation, storage, and maintenance of wine. Their most important task was to age and preserve wine in wooden barrels, especially oak barrels.

With industrialization in the 19th century, the profession changed significantly. Advances in cellar technology, such as the introduction of stainless-steel tanks and modern filtration methods, led to a professionalization of wine production. Wine coopers no longer needed to specialize solely in wooden barrels but also had to understand chemical processes and hygiene standards.

In the 20th century, the profession became increasingly technical. The development of temperature-controlled fermentation tanks and analytical methods for quality control significantly transformed the work of wine coopers. Today, the job requires extensive knowledge of biology, chemistry, and modern cellar technology.

Is a wine cooper the same as a winemaker?

No, a wine cooper (or wine technologist) and a winemaker are two different professions, even though they are closely related. Another closely connected profession is the oenologist, which requires further studies or additional training.

Differences Between Wine Cooper and Winemaker:

- Winemaker:

- Grows vines and manages the vineyard.

- Takes care of the grapevines, monitors grape growth, and determines the optimal harvest time.

- Is often also responsible for winemaking, especially in smaller businesses.

- Wine Cooper (Wine Technologist):

- Primarily works in the wine cellar.

- Processes harvested grapes, controls fermentation, and manages wine aging and storage.

- Has in-depth knowledge of cellar technology, filtration, and bottling.

In large wineries or cellars, both professions often work hand in hand: the winemaker provides the grapes, while the wine cooper refines and ages the wine. In smaller family businesses, one person may take on both roles.

Wood Cooper

A wood cooper (also simply “cooper,” sometimes called “barrel maker” or “tonnellier”) is a craftsman who manufactures and repairs wooden barrels and other wooden containers. These barrels have traditionally been used for storing and transporting liquids such as wine, beer, cider, and spirits.

History of the profession

Coopering is an ancient craft dating back to antiquity. The Romans already used wooden barrels to transport wine and oil. In the Middle Ages, coopers were highly valued, as almost every town and monastery relied on their barrels—not only for beverages but also for storing food such as fish or grain.

In the 19th and early 20th centuries, the profession reached its peak, as wooden barrels were the primary storage and transport containers for many products. However, with industrialization and the introduction of metal and plastic containers, the importance of coopering declined. Today, it is a highly specialized trade, particularly in wine and whisky production, where wooden barrels are still valued for their impact on the flavor of the final product.

The profession has become so rare that apprentices in Germany must attend vocational school in Austria because there is no longer a school for coopers in Germany!

Techniques and Modern Importance of Cooperage

Techniques of Cooperage

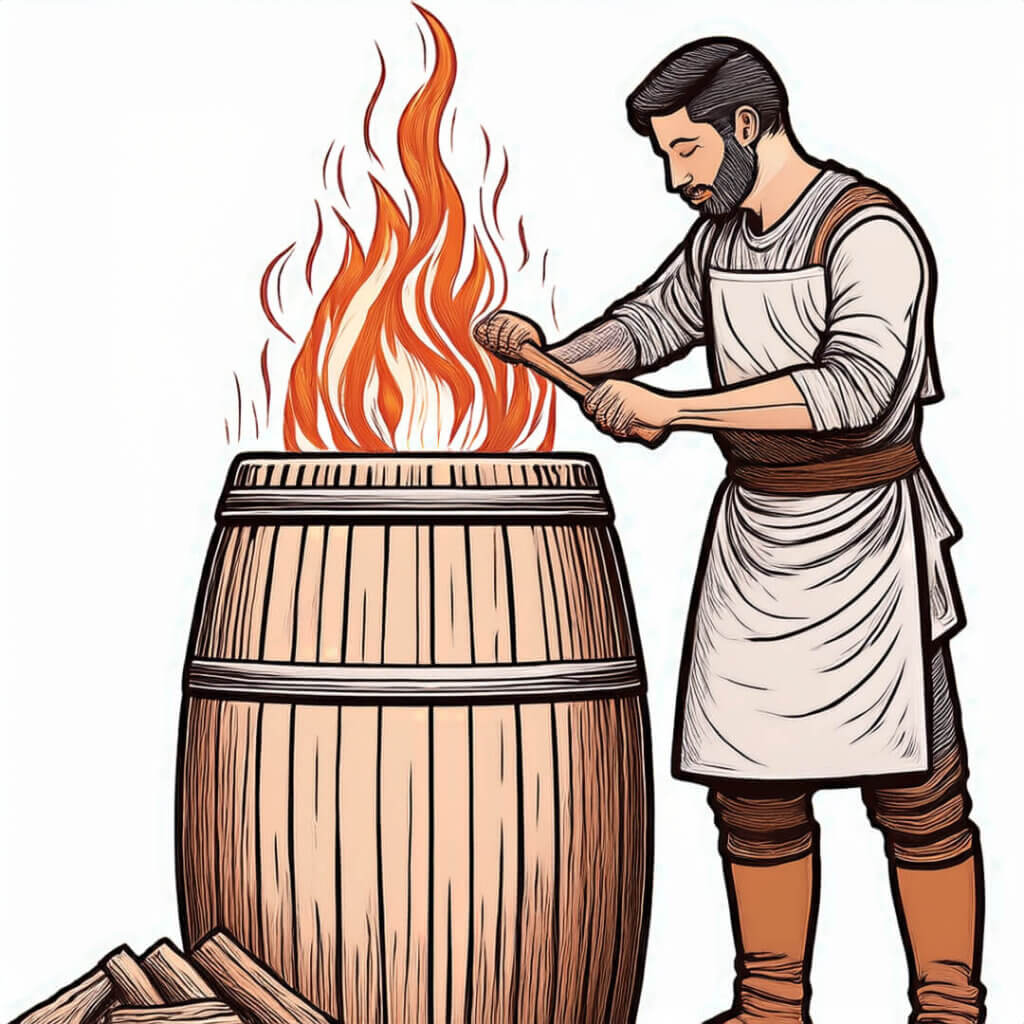

A wood cooper crafts barrels and other wooden containers using precise craftsmanship. This includes the following techniques:

- Selecting the Wood:

- Oak is most commonly used due to its durability, longevity, and aromatic properties. Other woods, such as chestnut or cherry, are used less frequently.

- Making the Staves:

- The barrel staves (individual wooden pieces) are cut, shaped, steamed, and bent into form.

- This is traditionally done using fire or steam to increase flexibility.

- Assembling the Barrel:

- The staves are held together by metal hoops without nails or glue.

- The inside of the barrel can be charred (toasting) to create flavors for wine or whisky aging.

- To ensure the barrel is watertight, a mixture of flour and water, along with reeds, is used—especially around the barrelhead.

- Leak Test & Finishing:

- The barrel is tested with water to ensure it is leak-proof.

- If requested, or for specific wood types and large barrels, a breathable and food-safe varnish may be applied.

Modern importance of the profession

Although industrialization has largely replaced wooden barrels with metal or plastic containers, there is still a strong demand for handcrafted barrels, especially in the following areas:

- Winemaking: High-quality wines often age in wooden barrels, as they absorb desirable flavors and enhance longevity.

- Whisky and spirits production: Barrel aging is essential for flavor development. Many distilleries use barrels made from special wood and/or with specific toasting levels.

- Craft beer & vinegar production: Some breweries and vinegar manufacturers are reviving the use of wooden barrels for aging.

- Special uses: Coffee beans are sometimes steamed in wooden barrels, Tabasco is aged in barrels, soy sauce ferments in barrels, and much more.

- Furniture & decoration: Old wine barrels are often repurposed into tables, shelves, flower planters, and more.

The profession of the wood cooper is now a niche trade that has survived mainly in regions with strong wine or whisky production. There are specialized training paths, but the number of cooperages is very low.

Conclusion

Comparison: wine cooper vs. wood cooper

| Feature | Wine cooper (wine technologist) | Wood cooper (barrel maker, tonnelier) |

| Field of work | Winemaking and cellar management | Manufacturing and repairing wooden barrels |

| Workplace | Wineries, wine estates, sparkling wine cellars | Cooperages, barrel workshops, wine cellars |

| Main tasks | Fermentation, aging, filtration, and bottling of wine | Wood processing, barrel construction, repair, and restoration |

| Materials used | Grapes, wine, stainless steel tanks, wooden barrels | Wood, metal hoops, barrel-making tools, fire |

| Technical knowledge | Cellar technology, fermentation processes, hygiene | Woodworking, barrel sealing, bending and toasting staves |

| Products | Wine, sparkling wine, cider, spirits | Wine barrels, beer barrels, wooden vessels for vinegar, whisky, and spirits |

| History | Evolved from winemaking, often practiced in monasteries | Since antiquity, used for making wooden barrels for transport and storage |

| Training | 3-year apprenticeship as a wine technologist | 3-year apprenticeship as a cooper/barrel maker (school located in Austria) |

| Modern importance | Highly in demand in the wine industry | Niche profession, mainly for barrel production in wine & whisky |

The wine cooper processes wine and often uses barrels crafted by the wood cooper. Barrel makers ensure that high-quality barrels are produced, giving the stored products unique flavors.

Both professions are crucial to the wine and spirits industry, though wine coopers are more common today as many wines are aged in stainless steel tanks. You can identify this by checking if the wine label states “aged in barrique.”

Would you like to learn more about the profession or even visit a cooperage? We also offer guided tours for small and large groups—inquire here!

Cheers!